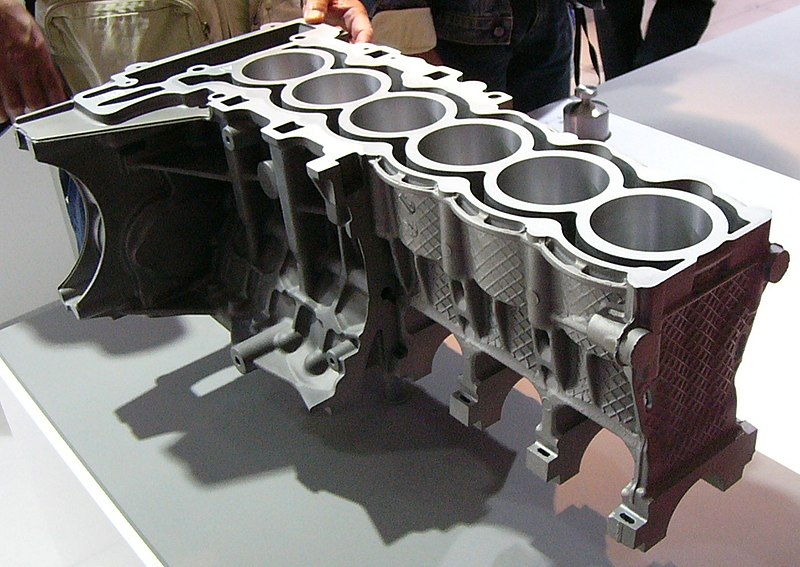

The core of diecasting is the mold, known as a"die" that is meticulously crafted from reinforced steel that is able to endure the tough conditions encountered in the process of casting. The shape of the die is vital, since it has to accommodate the melting metal's flow and solidification while keeping tight tolerances in order to guarantee accuracy. In the process of diecasting, metals such as aluminum, zinc, magnesium and copper are heated up until they melt. This molten metal is then placed into the mold cavity at high pressure, filling every nook and cranny of the mold. The rapid cooling and solidification of the metal result in parts that exhibit excellent dimensional accuracy and a perfect surface finish, usually without the need for further machining or finishing processes.

One of the most significant advantages of diecasting is its efficacy in production of large quantities. Once the dies are created and the process begins, it can be repeated several times and with very little variations between components. The repeatability is crucial for businesses that need large quantities of uniform components. Additionally, diecasting is renowned as a material that is efficient. It produces lesser waste than other techniques for forming metal because any metal that is not used is able to be reused and recycled. This is not only a way to reduce material costs but also supports green manufacturing practices. Diecasting's speed and precision diecasting make it the ideal method for making large amounts of components quickly and efficiently so that the manufacturers are able to meet tight production schedules and marketplace demands.

Diecasting can also produce components with excellent mechanical characteristics. The speedy cooling process of molten metal through the casting process produces fine grain structure that increases the toughness and endurance of the finished product. Dies makes diecast parts appropriate for uses that require high performance and reliability. In the automotive sector they are employed in transmissions, engines as well as structural components, where their weight-to-strength ratio plays a crucial role to ensure safety and efficiency of vehicles. Similarly, in the aerospace sector diecast parts contribute to the development of lighter but robust structures, essential for optimizing the efficiency of fuel and performance. To gather more details please look at Senadiecasting

Diecasting's flexibility extends into a variety of applications across different sectors. In the automotive industry Diecast components play an integral role in the building of motors, transmissions and structural parts. They contribute to the production of less weight and more efficient vehicles. In the electronics sector the use of diecasting can be used to make heat sinks connectors, and housings providing optimal thermal management and durability for electronic devices. The industry of consumer goods benefits from diecasting, with applications ranging from household appliances to power tools, toys and even power tools. The process's adaptability to various metals as well its ability to make parts with complex design make it ideal for various applications, each profiting from the distinctive advantages diecasting has to offer.

Diecasting is an essential manufacturing technique that blends the highest level of precision, efficacy and versatility. Its capability to make complex, high-quality components with excellent mechanical properties makes it indispensable to many sectors. The efficiency of diecasting when it comes to mass production, with its cost and material benefits, justifies its significance in manufacturing today. Since the need for high-quality and reliable components continues to grow, diecasting will remain a key technology driving innovation and enabling the production of advanced products that meet the evolving needs of the marketplace. With its constant advancement and use, diecasting exemplifies the interaction between engineering and manufacturing knowledge, establishing its role in the future of industrial production.